How to Control the Solar Water Pump Flow?

Solar water pumps offer great advantages for businesses, particularly in agriculture, industrial applications, and remote site management. However, the true efficiency and cost-effectiveness of these systems rely on one critical factor: precise water flow management.

Whether it's optimizing irrigation for maximum crop yield, ensuring a consistent water supply for livestock, or maintaining specific pressure in a water transfer system, matching water output to demand is significant.

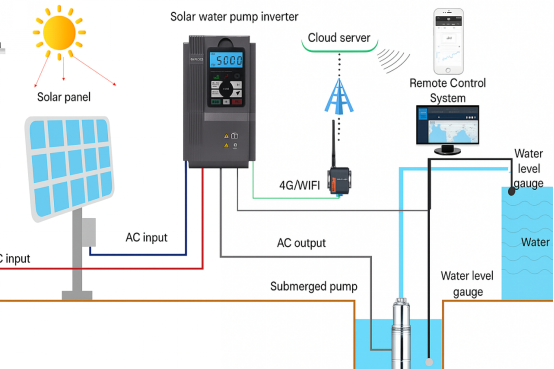

Achieving this level of control requires sophisticated solutions, and at the forefront of these is the solar water pump inverter. This device transforms the variable power from solar panels into the precise control needed for optimal pump performance, a key component we'll explore in detail.

How Does a PV Water Pumping System Work?

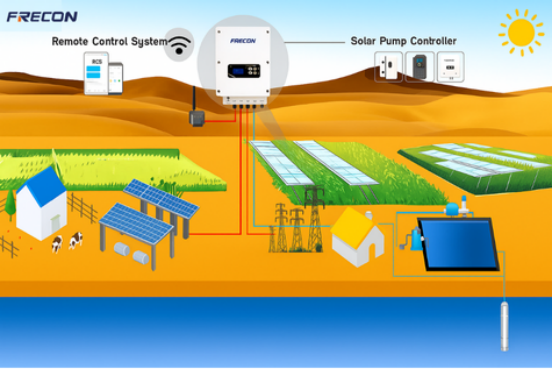

A Photovoltaic (PV) water pumping system uses the sun's energy to directly power a water pump. It's an off-grid solution, and thus ideal for remote areas without access to the conventional power grid, such as agricultural fields for irrigation, mountainous regions needing a water supply, or pastures for livestock drinking water.

The core principle is straightforward: solar energy transforms into electrical energy, which then drives the pump's mechanical energy to draw water.

Solar power → Electrical Energy → Mechanical Energy in Pump → Draw Water

Components of Solar Water Pump System

Component | Function | How to Choose |

Solar Panels (PV Modules) | The primary power generation units convert light energy directly into DC electricity. | Power Calculation: Total power should be based on pump requirements (e.g., a 1.5kW pump needs 2-3kW PV, allowing 20% redundancy). Efficiency: Prioritize monocrystalline silicon panels (18%-22% efficiency). |

Water Pump | The actuator that performs the water pumping, available as DC (Direct Current) pumps or AC (Alternating Current) pumps. | DC Pumps: Suited for direct connection to solar PV without an inverter; commonly centrifugal and deep well pumps. AC Pumps: Require an inverter (VFD) to convert DC to AC; generally preferred for larger flow rate applications. Performance Matching: Select based on specific head (vertical lift) and flow rate (volume per hour) requirements (e.g., 50m head, 10 tons/hour flow). |

Controller (Optional but Recommended) | Regulates electrical output, provides system protection (overload, short circuit), and often includes MPPT (Maximum Power Point Tracking) functionality. | MPPT Advantage: Highly recommended as it significantly boosts power generation efficiency by 10% to 30%. Power Rating: Should be at least 1.2 times the rated power of your water pump. |

Energy Storage Battery (Optional) | Stores excess electrical energy from solar panels for use during cloudy days or at night. | Capacity Configuration: Based on continuous operation needs during sunless periods (e.g., for 3 cloudy days: pump power × daily working hours × 3 days). Battery Type: Lithium batteries are highly recommended due to their longer lifespan (typically 5-8 years). |

How to Control the Flow Rate of a Water Pump?

Achieving optimal water management with solar pumps involves implementing various control strategies. These methods empower businesses to fine-tune water delivery, conserve resources, and protect their investment.

1. Solar Pump Inverter/Variable Frequency Drive (VFD)

At the forefront of modern solar pump control is the Variable Frequency Drive (VFD), often referred to as a solar pump inverter. This intelligent device is crucial for optimizing pump performance by dynamically adjusting the motor speed based on available solar power and desired flow rates.

Rather than simply turning the pump on or off, an inverter allows for precise modulation of water flow by changing the frequency and voltage supplied to the pump motor.

Recommended Solution: FRECON PV580 Series Solar Pump Inverter

For businesses seeking a robust and highly efficient solution, we recommend the FRECON PV580 series IP65 solar pump inverter.

Engineered for demanding environments, the PV580 boasts an IP65 design for outdoor installation and is compatible with both DC and AC power inputs. Its optimized MPPT (Maximum Power Point Tracking) algorithm achieves over 99% efficiency, ensuring you extract the most power from your solar panels.

The PV580 offers comprehensive protection functions against overcurrent, overvoltage, and short circuits, guaranteeing reliable, automatic, and unattended operation.

For smaller systems (below 2.2KW), a built-in booster module can reduce the number of solar panels required, further lowering initial investment costs. Optional GPRS remote monitoring capabilities provide real-time status checks and remote control, offering unparalleled operational oversight.

2. Mechanical Flow Control

While less precise than inverters, mechanical methods offer straightforward ways to manage pump output.

l Throttling Valves: By partially closing a valve on the pump's discharge line, you can restrict water flow. For centrifugal pumps, this reduces the flow rate based on the pump's performance curve. While simple, excessive throttling can lead to increased energy consumption and pump wear if not managed correctly.

l Bypass Lines (Recirculation Loops): Implementing a recirculation loop or bypass line from the reservoir back to the source, equipped with a pressure bypass valve, ensures the pump always operates at its minimum required flow, even when demand is low. This can prevent pump damage due to dry running or cavitation.

3. Water Storage/Tank Systems

Integrating water storage tanks into your solar pumping system provides a crucial buffer, decoupling water availability from immediate solar irradiance.

l Demand Smoothing: Water can be pumped and stored during peak sunshine hours, then used as needed, even after dark or during cloudy periods. This ensures a consistent supply regardless of solar fluctuations.

l Overflow Prevention: Utilizing control mechanisms like float switches in the storage tank can automatically stop the pump when the tank is full, preventing overflow, conserving groundwater, and reducing unnecessary pump operation and wear. A second outlet valve at the tank bottom can provide an emergency discharge.

l Flexible Distribution: Stored water can be distributed by gravity or through a secondary pressure system to meet specific site requirements.

4. Smart Controllers & Automation

Beyond the inverter, advanced control systems and automation elevate the efficiency of solar water pumping.

l Float Switches: As mentioned, simple float switches are effective for basic ON/OFF control based on tank levels, preventing overflows and dry running.

l Pressure Sensors: For systems requiring consistent pressure, sensors can monitor pipeline pressure and signal the inverter to adjust pump speed accordingly, maintaining a desired output.

l Timers and Programmers: Allow for scheduled pumping operations, aligning water delivery with specific irrigation cycles or demand patterns.

l Remote Monitoring: Advanced systems, like those with GPRS functionality (as seen in the FRECON PV580), enable remote oversight, data logging, and troubleshooting, offering significant operational advantages for large-scale or geographically dispersed installations.

What Controls the Flow Rate in a Pump?

The water flow rate, how much water your system can deliver, is not static. It's a dynamic output shaped by a combination of environmental conditions and system design.

1. Solar Irradiation (Sunlight Intensity)

The most direct and significant factor influencing solar pump flow rate is the amount of sunlight hitting your solar panels. Water production directly correlates with solar irradiation:

l Daily Cycle: As the sun rises, water production increases, reaching its peak during the brightest part of the day, and then gradually tapers off as the sun sets.

l Environmental Obstructions: Factors like cloud cover, smoke from wildfires, or even dirt accumulation on the solar panels can significantly reduce the amount of sunlight absorbed, directly impacting the power generated and, consequently, the water flow. This highlights the importance of robust planning and potentially incorporating water storage (2 to 5 days recommended) to mitigate environmental variability.

2. Total Dynamic Head (TDH)

Total Dynamic Head refers to the total equivalent height that the pump must lift water. This is a critical design parameter determined during the planning stages and directly impacts the required pump power and achievable flow rate. TDH includes:

l Vertical Lift (Static Head): The actual vertical distance from the water source to the discharge point.

l Friction Loss: The resistance created by water moving through pipes, valves, filters, and fittings. Longer pipes, smaller diameters, and numerous bends or components increase friction loss.

A higher TDH demands more power from the pump, which can reduce the achievable flow rate for a given power input.

3. Pump Curve/Characteristics

The curve illustrates its relationship between head, flow rate, and efficiency at various operating speeds. Matching the pump's characteristics to your system's specific TDH and desired flow rate is essential for optimal performance. A mismatch can lead to inefficient operation or insufficient water delivery.

4. Pipe Diameter and Length

Influence the friction loss component of the Total Dynamic Head.

l Pipe Diameter: A smaller pipe diameter for a given flow rate will result in higher water velocity and significantly increased friction loss, thus reducing the effective flow rate.

l Pipe Length: The longer the pipe, the greater the cumulative friction loss. Optimizing pipe sizing is vital to minimize energy waste and maximize flow.

5. System Components (Valves, Filters, Fittings)

Each component installed in the pumping line (e.g., valves, filters, elbows, T-junctions) introduces additional friction and pressure loss. While necessary for system function and control, their selection and placement should aim to minimize unnecessary resistance to water flow.

6. Water Level (Source and Destination)

The varying water levels at both the source (e.g., well, bore, river) and the destination (e.g., storage tank, irrigation field) directly affect the vertical lift component of the Total Dynamic Head. Fluctuations in these levels will alter the pump's required workload and, consequently, its instantaneous flow rate.

7. Inverter Efficiency and Settings

As we mentioned earlier, the solar pump inverter plays a crucial role in maximizing water flow, particularly through its MPPT (Maximum Power Point Tracking) capabilities.

Contact FRECON for More Control Solutions

For businesses seeking to implement or upgrade their solar water pumping systems with cutting-edge technology and robust industrial control solutions, we invite you to explore FRECON's range of products, including the highly efficient PV580 series solar pump inverter.

Visit FRECON today to learn more about our industrial control solutions and how we can help you achieve optimal performance for your water management needs.