1、 Preface

Industrial washing machine from the ordinary to the development of automatic type, the automatic industrial washing machine mostly adopts multiple double speed AC motor, because of the characteristics of simple structure, stable, cheap, widely used. But its shortcoming is the speed adjustment performance is bad, the speed catastrophe is big, the vibration is big. With the development of power semiconductor technology, AC inverter has been widely used in industrial washing machines in recent years.

2、 Process requirements

According to the industrial washing machine load low speed high torque starting and external control interface, FRECON FR200X series inverter can well satisfy the requirements of high torque, multi speed, wide voltage range, high temperature and convenient means of communication, the successful implementation of the low speed high-speed washing, drying and other processes, through practice, to achieve a very good use effect.

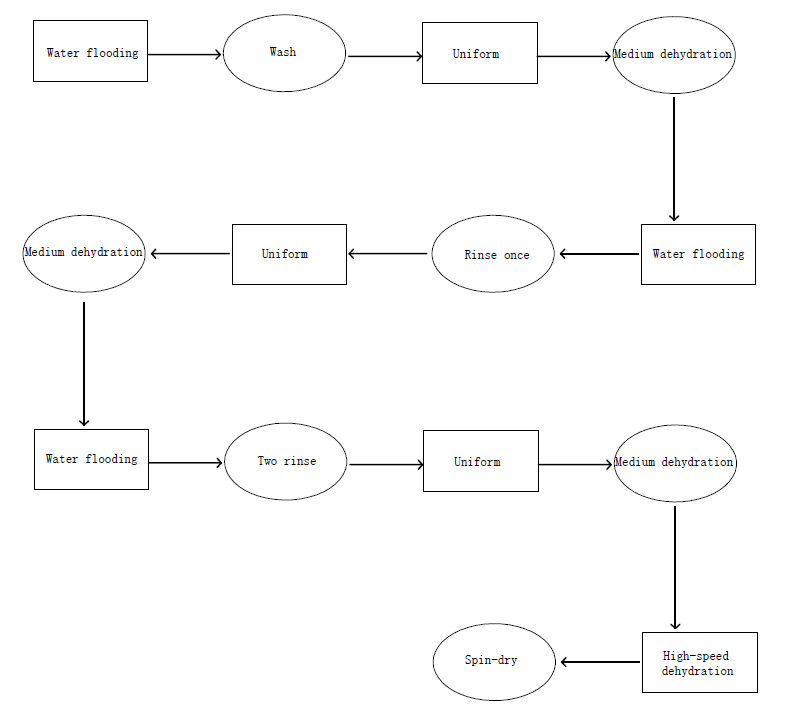

The washing process for this type of industrial washing machine is as follows:

Figure 2-1

3、 Control scheme

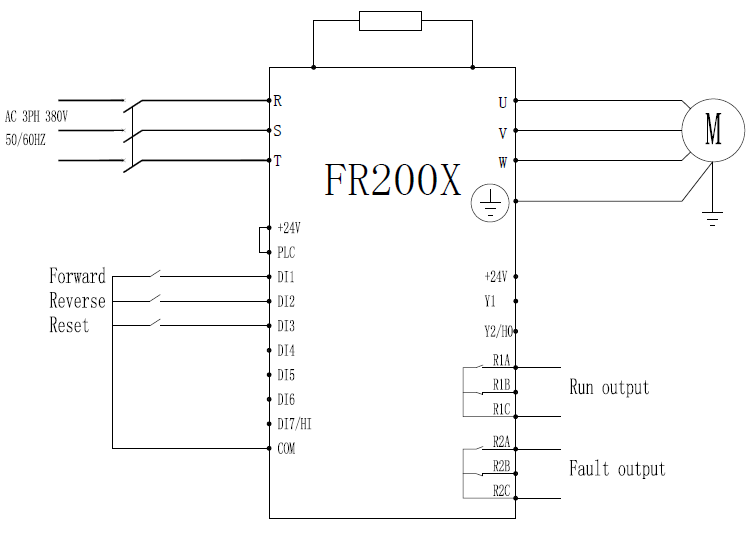

Figure 3-1

The industrial washing machine itself has built-in dedicated control computer for control. The running speed of each process stage set directly in the inverter, taking into account the washing requirements of different washing time, simple PLC built-in dedicated control computer running time of each process stage by the industrial washing machine is controlled by inverter to complete or.

Process parameter table at each stage of washing machine that realized by inverter control:

Technological process | Frequency | Time |

Water flooding | Stop | 3 min |

Wash | 10Hz | 25 min |

Uniform | 25Hz | 1.5 min |

Medium dehydration | 80Hz | 2 min |

Water flooding | Stop | 3 min |

Rinse once | 16Hz | 5 min |

Uniform | 25Hz | 1.5 min |

Medium dehydration | 80Hz | 2 min |

Water flooding | Stop | 3 min |

Two rinse | 16Hz | 5 min |

Uniform | 25Hz | 1.5 min |

Medium dehydration | 80Hz | 2 min |

High-speed dehydration | 150Hz | 5 min |

4、 Main parameter settings of inverter

Function Code | Parameter Name | Setting Range | Description |

F01.01 | Master Frequency Command Source | 5 | PLC |

F01.08 | Maximum frequency | 150Hz | The maximum frequency is150 |

F01.09 | Upper limit frequency | 150Hz | The upper limit frequency is 150 |

F02.00 | Run command | 1 | Terminal control |

F04.00 | Function of terminal DI1 | 1 | Running forward |

F04.01 | Function of terminal DI2 | 2 | Running reverse |

F04.02 | Function of terminal DI3 | 7 | Fault reset |

F05.02 | Relay 1 output function | 1 | Drive is running |

F05.03 | Relay 2 output function | 2 | Fault Output |

F12.00 | Reference 0 | 0Hz | Water flooding speed |

F12.01 | Reference 1 | 10Hz | Washing speed |

F12.02 | Reference 2 | 25Hz | Uniform speed |

F12.03 | Reference 3 | 80Hz | Medium dehydration speed |

F12.04 | Reference 4 | 0Hz | Water flooding speed |

F12.05 | Reference 5 | 16Hz | Rinse once speed |

F12.06 | Reference 6 | 25Hz | Uniform speed |

F12.07 | Reference 7 | 80Hz | Medium dehydration speed |

F12.08 | Reference 8 | 0Hz | Water flooding speed |

F12.09 | Reference 9 | 16Hz | Two rinse speed |

F12.10 | Reference 10 | 25Hz | Uniform speed |

F12.11 | Reference 11 | 80Hz | Medium dehydration speed |

F12.12 | Reference 12 | 150Hz | High-speed dehydration |

F12.18 | Running time of step 0 | 180s | Water flooding time |

F12.19 | Running time of step 1 | 1500s | Washing time |

F12.20 | Running time of step 2 | 90s | Uniform time |

F12.21 | Running time of step 3 | 120s | Medium dehydration time |

F12.22 | Running time of step 4 | 180s | Water flooding time |

F12.23 | Running time of step 5 | 300s | Rinse once time |

F12.24 | Running time of step 6 | 90s | Uniform time |

F12.25 | Running time of step 7 | 120s | Medium dehydration time |

F12.26 | Running time of step 8 | 180s | Water flooding time |

F12.27 | Running time of step 9 | 120s | Two rinse time |

F12.28 | Running time of step 10 | 90s | Uniform time |

F12.29 | Running time of step 11 | 120s | Medium dehydration time |

F12.30 | Running time of step 12 | 300s | High-speed dehydration time |