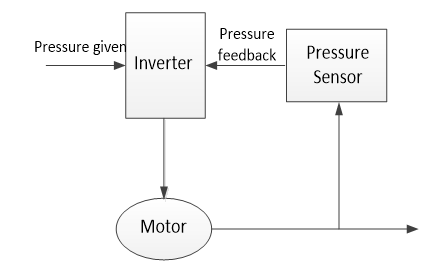

1、 Control principle and scheme

Compared with regulating valve to realize constant pressure water supply, energy saving effect is remarkable (can be calculated according to specific conditions):

(1) Starting balance, the starting current can be limited to the rated current, so as to avoid the impact on the power grid when starting;

(2) As the average speed of the pump is reduced, the service life of the pump and valve can be prolonged;

(3) The water hammer effect at starting and stopping can be eliminated;

Generally speaking, when a inverter control of a motor, just make the inverter motor capacity and the actual capacity of the motor can be consistent with. When a inverter also controls two motors at the same time, in principle, the motor capacity of the inverter should be equal to the sum of the capacities of the two motors. But if the peak load the water ratio of two water pumps at full speed is a lot of difference, may be appropriate to reduce the capacity of inverter, it should be noted that there is sufficient capacity.

Although the pump at low speed operation, the motor operating current is small. However, when the user's water consumption change frequently, the motor will be in frequent or, deceleration state, and rise, the rated current of current deceleration can be slightly more than the motor, resulting in motor overheating. Therefore, the motor thermal protection is required. For this because of the frequent rise, drop speed and accumulated temperature, the electronic thermal protection function in the inverter is difficult to play a protective role, thermal protection should be used for motor thermal relay.

The main function of the preset, the highest frequency in the rated frequency of the motor is the highest frequency of inverter. L, deceleration time adjustment in converter using a built-in PID. L, deceleration time should be set shorter, so as not to affect the dynamic response of the PID controller. The control principle of the following decision:

2、 Inverter control features

n Power saving: optimized energy-saving control software, enabling the pump to achieve maximum energy saving operation;

n Water saving: according to the actual situation of water use, set the pipe network pressure, automatically control the water pump output, reduce the water running, leakage phenomenon;

n Operation is reliable: the soft starting of the pump is realized by the inverter, so that the water pump can realize no impact switching from the frequency to the inverter, prevent the impact of the pipe network, and avoid the pipe network pressure exceeding the limit and burst the pipe;

n Network function: using Chinese configuration software, real-time monitoring of each site, such as voltage, current, frequency, pressure and flow. And can accumulate each site's electricity accumulation of each pump out the water, at the same time to provide various forms of print statements, for statistical analysis;

n Control flexible: sectional water supply, regular water supply, manual selection of work (peripheral control circuit is not available);

n Self perfect protection function: such as a pump failure, take the initiative to send alarm information to the host computer, and start the standby pump to maintain water balance. If the control system fails, the user can directly operate the manual system, in order to maintain the water supply.

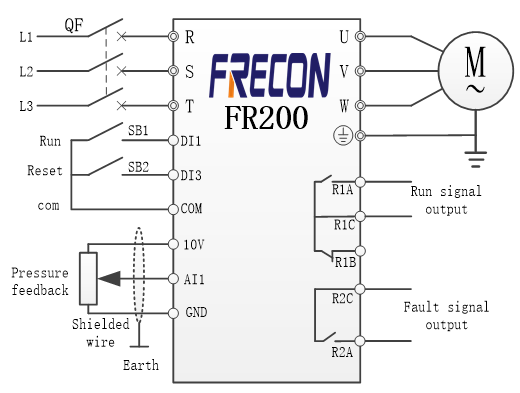

3、 Reference wiring diagram

Figure 2-2

4、 The reference parameter settings

Param | Parameter Name | Setting Range | Explain |

F00.08 | Motor control mode | 0 | Voltage/Frequency (V/F) control |

F01.01 | Master Frequency Command Source | 6 | Process PID output |

F02.00 | Run command | 1 | Terminal control |

F02.02 | Reverse-proof action | 1 | Reverse disabled |

F09.00 | V/f curve setting | 6 | 2.0nd power V/F |

F05.02 | Relay 1 output function | 1 | Drive is running |

F05.03 | Relay 2 output function | 1 | Fault output |

F13.00 | PID setting | 0 | PID digital setting |

F13.01 | PID digital setting | * | setting pressure (Percent of full scale) |

F13.02 | PID feedback | 0 | AI1 |

F13.03 | PID setting feedback range | * | The range of pressure gauge |

F13.04 | PID action direction | 0 | Direct action |

F13.08 | Proportional gain | * | According to the actual situation at the scene |

F13.09 | Integration time | * | According to the actual situation at the scene |

F13.22 | PID output frequency upper limit | * | According to the actual situation at the scene |

F13.23 | PID output frequency lower limit | * | According to the actual situation at the scene |

F13.24 | Detection value of PID feedback loss | * | According to the actual situation at the scene |

F13.25 | Detection time of PID feedback loss | * | According to the actual situation at the scene |