A sanding machine is a device that uses sandpaper or sanding belts to sand and polish the surface of workpieces. It is widely used in processes such as wood polishing and metal deburring, and serves as a crucial tool in the building materials, furniture, and metal processing industries. Sanding machines can be categorized into hand - held and bench - top types based on their usage. To enhance performance, the FR500 Series Inverters from FRECON Electric can be employed for precise speed regulation, enabling efficient and stable processing, reducing energy consumption, and extending the service life of the equipment. This inverter meets the working condition requirements of sanding machines, effectively improving production efficiency and processing quality.

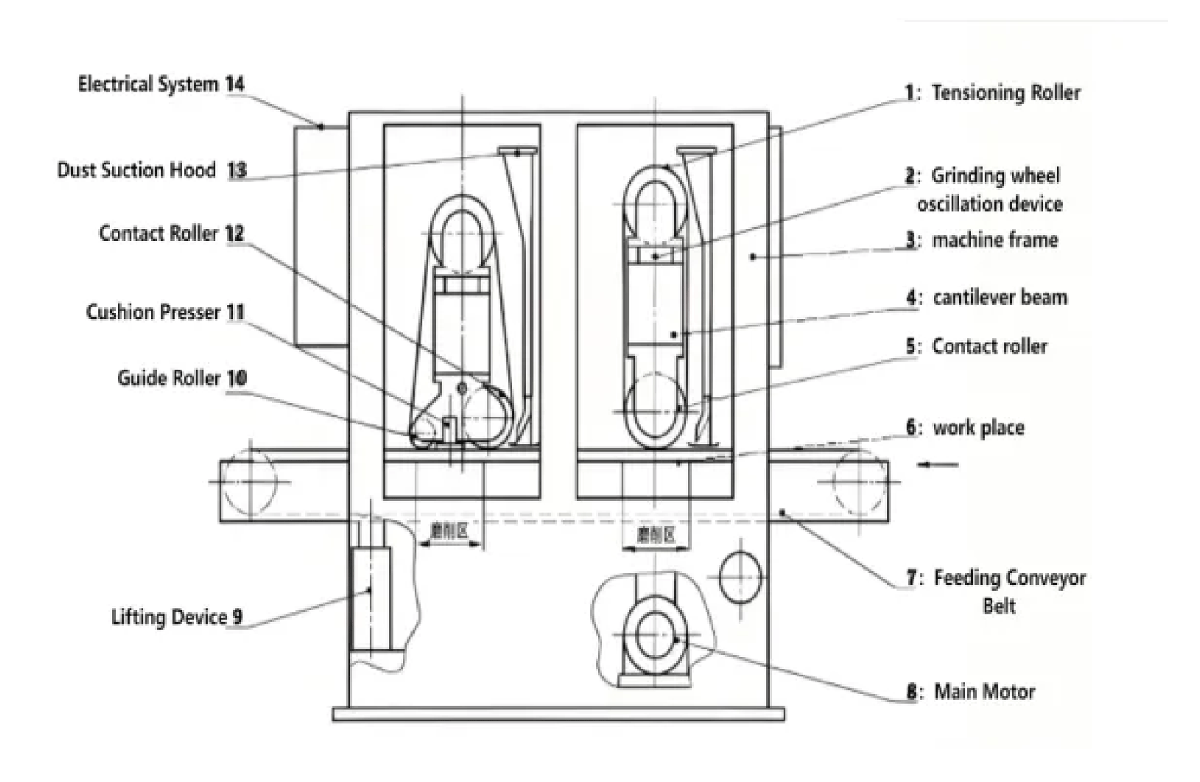

As a professional device for surface sanding and polishing, sanding machines find extensive application in wood processing, metal deburring, building materials processing, and other industries. Their core structure comprises a frame, a drive motor, grinding components like sanding belts/sanding discs, as well as auxiliary components such as a tensioning mechanism, a pressing device, a feeding system, and a dust suction device

The pressing device ensures uniform sanding.

The tensioning mechanism guarantees the stable operation of the sanding belt.

The feeding system (in some machine models) realizes automatic conveying.

The frame provides stable support, and the motor drives the sanding belt to run at high speed.

The dust suction device effectively collects dust and keeps the working environment clean.

The FR500 Series Inverter of FRECON can accurately adjust the speed and optimize processing efficiency and precision. Sanding machines are divided into hand - held and bench - top types according to the way they are used, and into wide - belt sanding machines, disc sanding machines and other types according to their functions, so as to meet the refined sanding needs of different industrial scenarios.

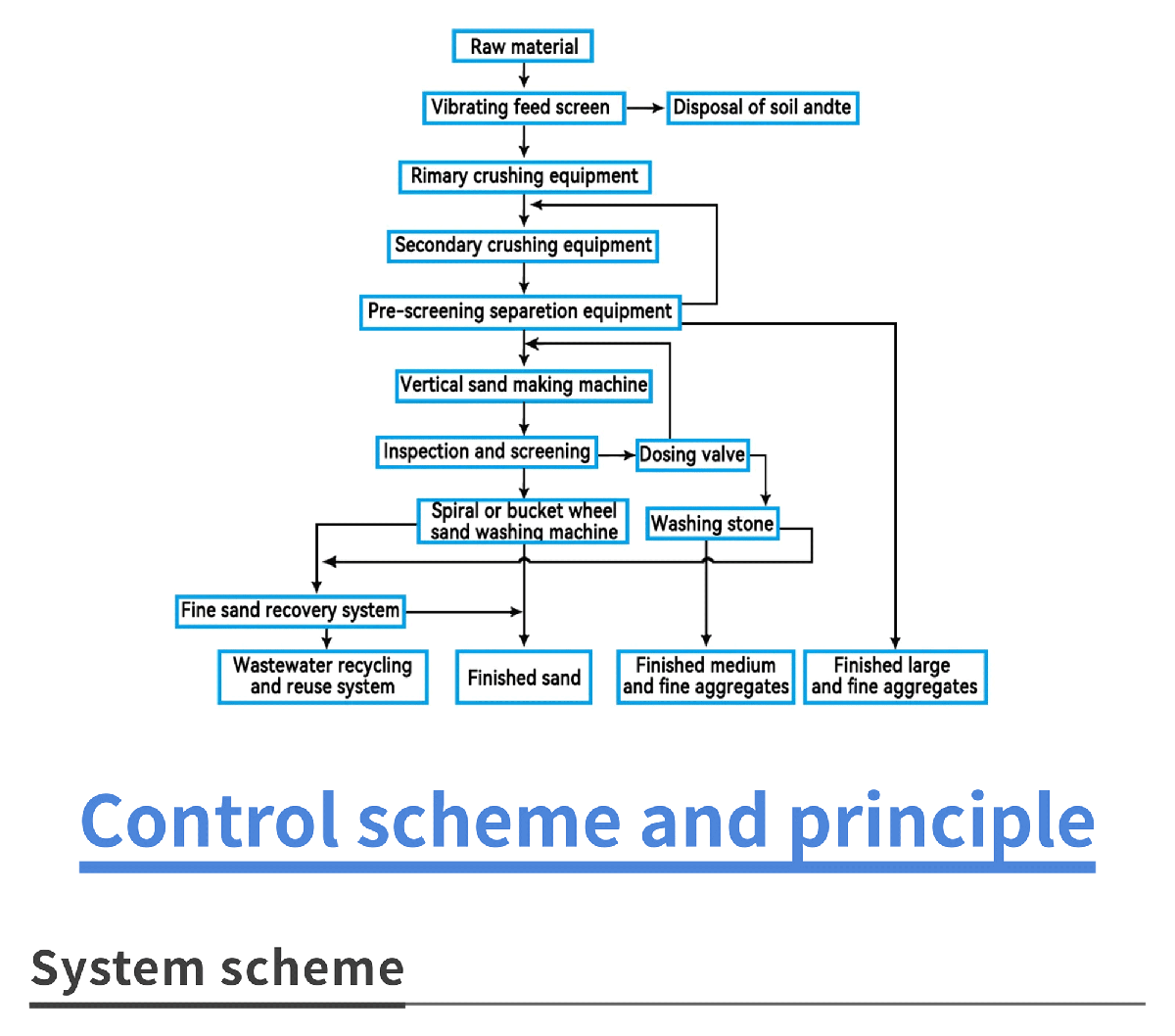

The sanding process is divided into three stages: rough grinding, fine grinding and polishing. Rough sanding quickly removes burrs and unevenness on the workpiece; medium sanding trims the surface and eliminates the marks left by rough sanding; fine sanding polishes the surface to make it smooth. Automatic sanding machines complete the processes continuously through the conveyor belt, while manual operation requires replacing the sanding belt step by step.

Key parameters include the grit size of the sanding belt, feeding speed, sanding belt pressure and dust removal system. During processing, it is necessary to monitor the surface quality in real time and adjust the parameters dynamically. Inverters are used to realize stepless speed regulation, which can adapt to a variety of materials and ensure precision and efficiency. The whole process needs to be combined with a dust suction system to keep the environment clean.

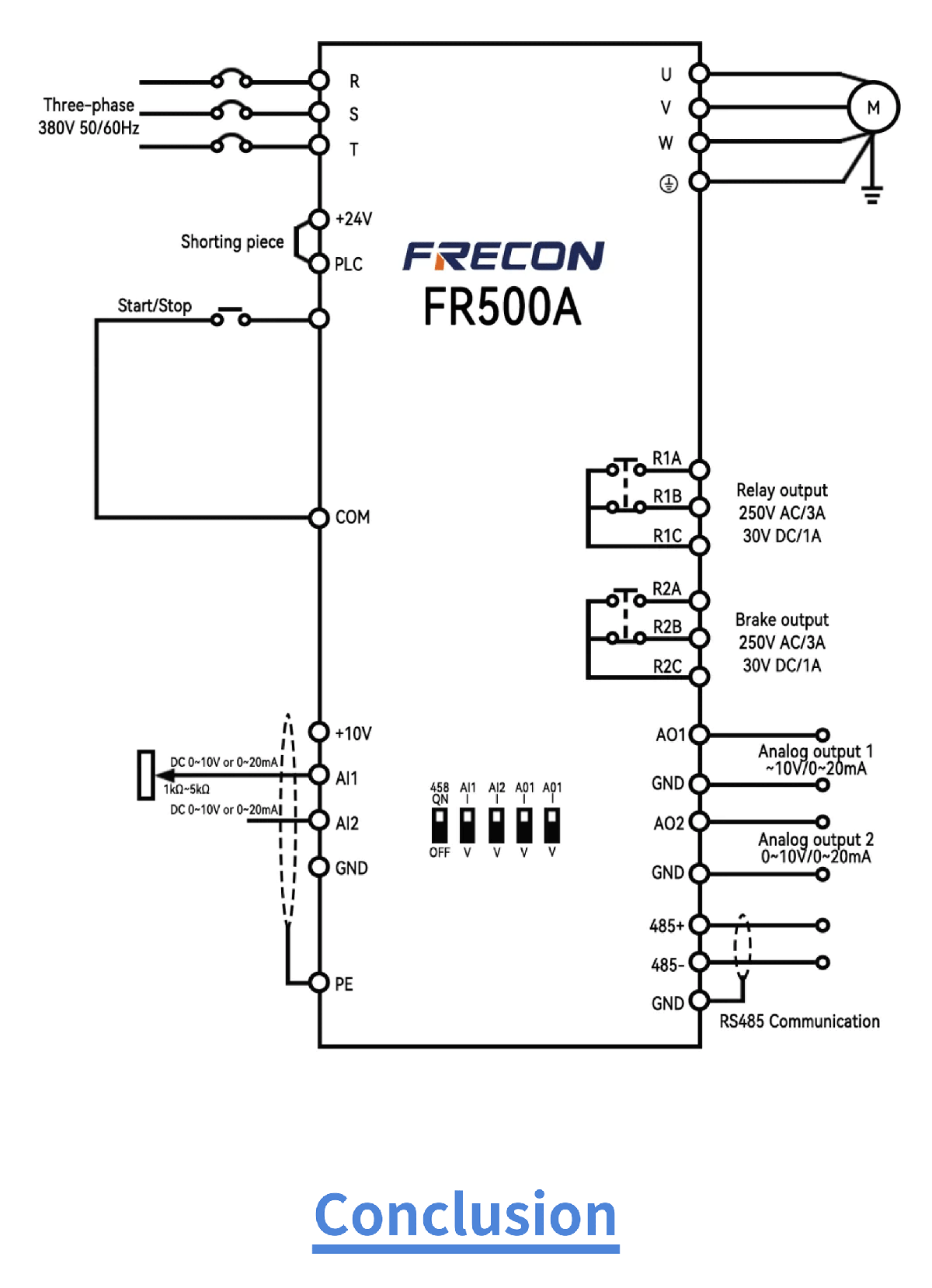

The automatic sanding machine equipped with FR500 Series Inverters controls the rotation speed of the sanding belt and the feeding speed through stepless speed change, which significantly reduces the labor demand and improves the production capacity. The feeding motor is integrated with an encoder to accurately calculate the processing volume and the position of the workpiece, ensuring precise positioning. The number of sanding frames and sanding heads can be increased or decreased as required. The PLC program coordinates multiple inverters to drive the sanding belt motors, and the stepless speed regulation function is used to meet the processing needs of different materials

The equipment automatically starts the air valve according to the change of processing volume to perform feeding compensation, which effectively deals with the wear of the grinding wheel, maintains stable sanding effect and ensures the consistent specifications of finished products. This design optimizes production efficiency, meets diverse processing requirements and improves the overall processing quality.

With excellent torque stability and strong overload capacity, the FRECON FR500 Inverter improves the fine sanding effect and efficiency of the sanding machine. Combined with the encoder to accurately calculate the processing volume and PLC control to realize stepless speed regulation, it can adapt to a variety of materials. The smooth acceleration and deceleration reduce mechanical wear, and the automatic feeding compensation ensures that the wear of the grinding wheel does not affect the specifications of the finished products. It has built - in protection functions against overcurrent, overvoltage, undervoltage and overload to ensure safe and reliable operation. This design optimizes production efficiency, reduces the failure rate, promotes the transformation of the sanding process towards high efficiency and environmental protection, and injects new impetus into the manufacturing industry.