1. Introduction

Escalators and moving walks are widely used in hotels, shopping malls, subways, railway stations, office buildings, halls, airports and other places, and play a very important role in facilitating customers and improving service quality. However, due to the particularity of its use occasions, some escalators are often in an idling state, which will waste a lot of electric energy, and also cause unnecessary wear and fatigue damage to escalator components (such as motors, gearboxes, handrails, etc). Therefore, FRECON Electric uses inverter to transform it for this deficiency.

The system requires the inverter to start and run smoothly, with good acceleration performance, large starting torque, and strong overload capacity. At the same time, when the inverter speed regulation system fails, the control system should automatically switch to power frequency operation to ensure the normal implementation of the escalator conveying function.

2. Technical requirements

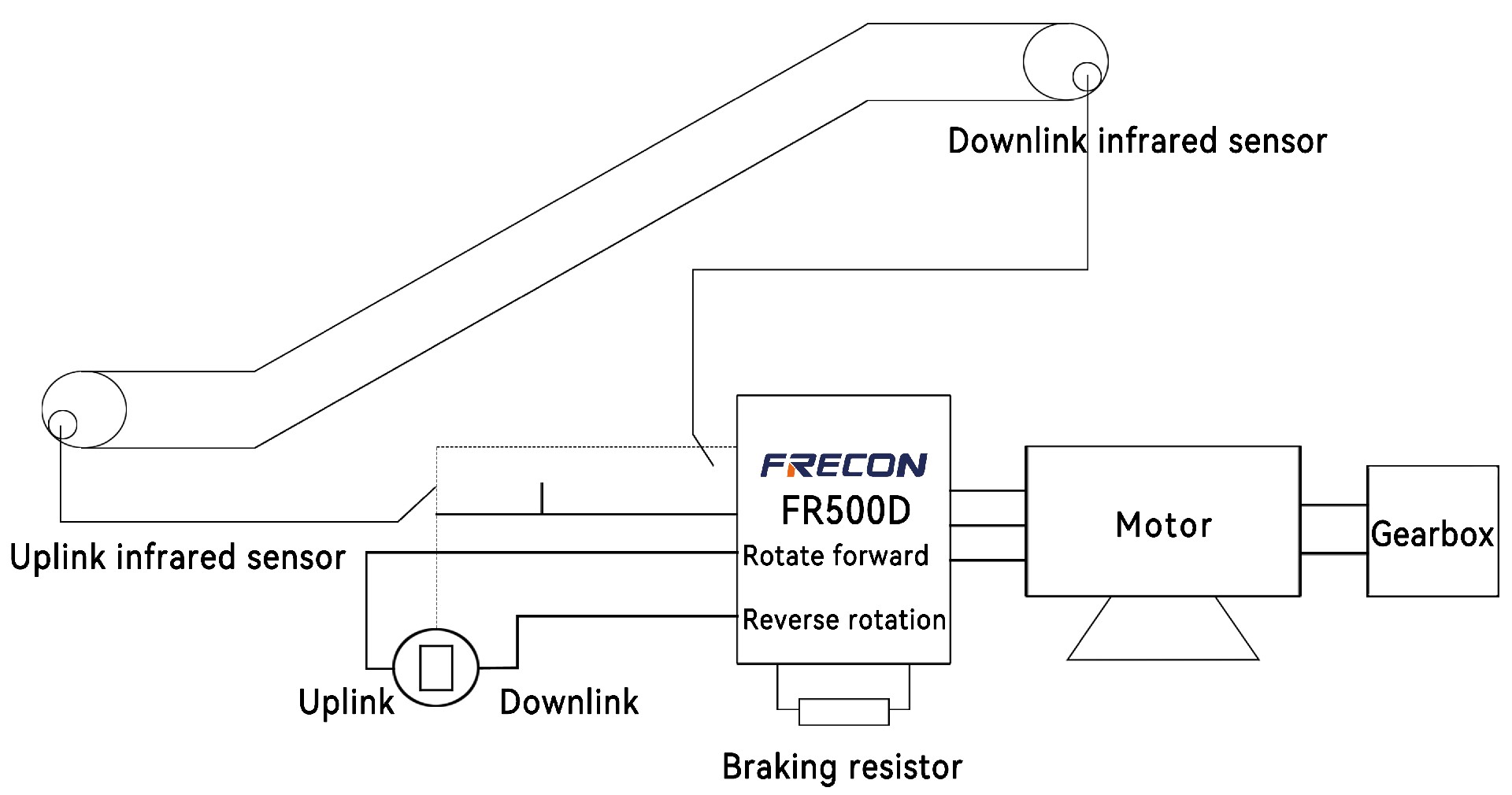

For passenger escalators, the peak period of use generally occurs in the afternoon and evening, and the utilization rate in other periods is low, which has considerable energy-saving space. According to the above transformation principles, considering the investment cost and automation level, the following inverter drive scheme is proposed: use FRECON FR500D series inverter to drive the elevator host, the inverter adopts multi-stage speed control mode, and set the main frequency (low speed), Multi-speed frequency 1 (high speed) two operating frequencies.

An infrared sensor switch is installed at the head and tail of the elevator. When passengers pass the elevator, the infrared sensor switch is triggered and send a switch signal to the inverter.

When there is passenger flow, the infrared sensor switch is triggered, and the inverter immediately accelerates to multi-speed frequency 1, and makes the elevator run at high speed.

When the elevator is running at high speed, the built-in timer of the frequency converter starts counting. If no passenger passes the elevator within the time period, the frequency converter will automatically switch to the multi-speed frequency 0 and run at low speed after the time is over. If a passenger triggers the photoelectric switch again during the timing of the timer, the timer will start counting again.

For the up and down of the elevator, the peripheral control adopts switch interlock to ensure the normal operation of the escalator system. In order to consume the excess energy generated during the downward movement or the braking process, the inverter needs to be connected with a braking resistor.

3. Control scheme

(1) Control schematic diagram

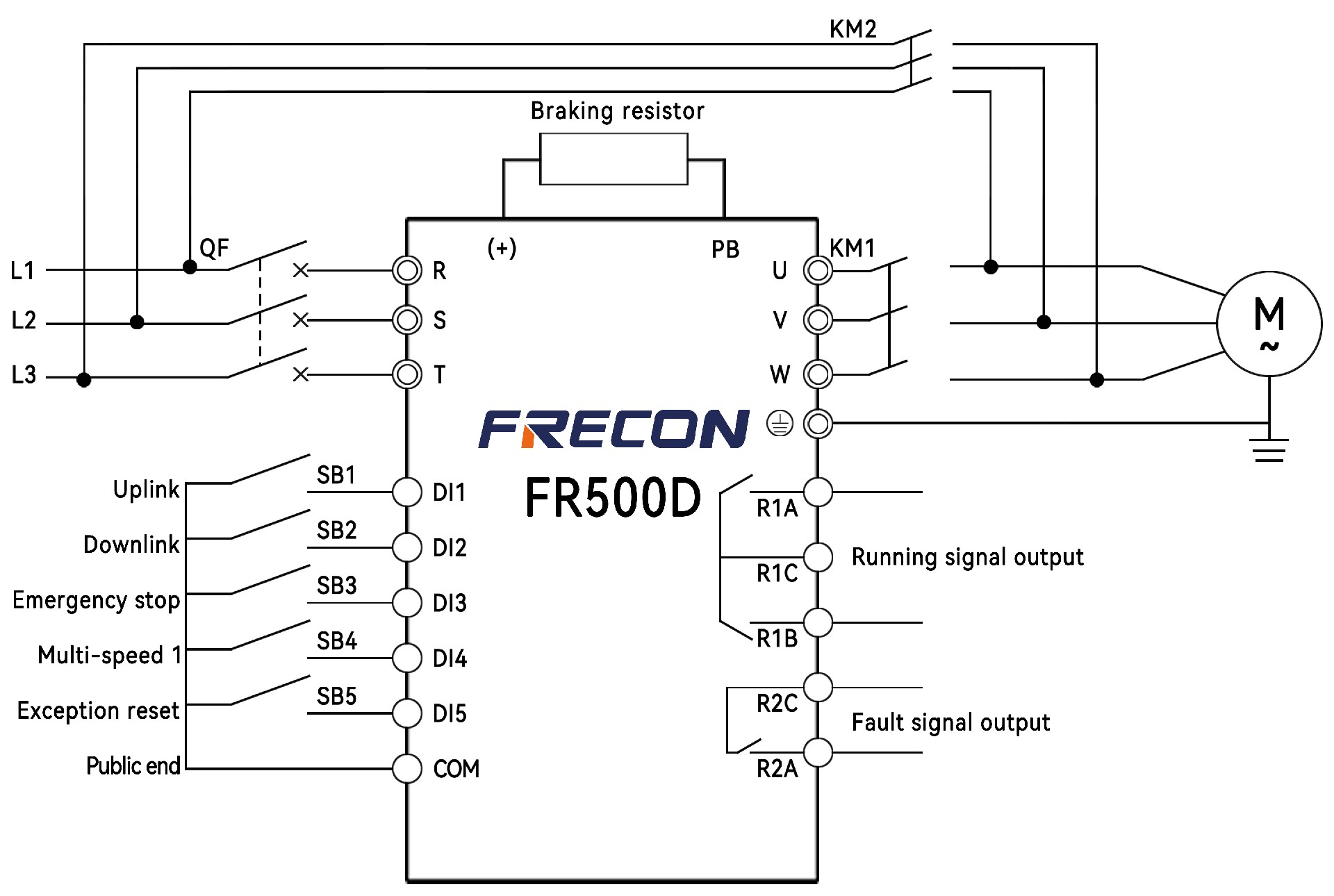

(2)Schematic diagram of electrical control

The motor circuit is equipped with "mains" and "power-saving" contactors, so that there are two working modes of "automatic" and "manual": in manual mode, the frequency converter does not work, and the whole system is manually started and stopped. frequency operation; in the automatic mode, the motor is directly driven by the frequency converter and operates with frequency conversion.When a fault occurs, the system automatically switches to power frequency operation.

4. Control advantage

(1) The scheme adopts FR500D inverter, which has the characteristics of low-frequency start-up, high torque, and fast response in the automatic torque control mode. When starting at 0.25Hz, the torque can reach 180% of the rated torque, which can fully meet the escalator process require.

(2) The inverter is a capacitive load, which can effectively improve the power factor of the motor and reduce reactive power loss.

(3) The inverter has various electronic protection devices such as short circuit, phase loss, overcurrent, overvoltage, overload, overheating, etc., and has rich fault alarm output functions, which can effectively ensure the normal operation of the entire system.

(4) When there is no passenger flow, the elevator runs at a very low speed, and the mechanical wear is greatly reduced.

(5) The process of starting, stopping and speed conversion of the frequency conversion drive system is smooth and smooth, with good comfort.

(6) There are two working modes: manual/automatic. In the event of a fault in the inverter, it can still continue to run in manual mode.

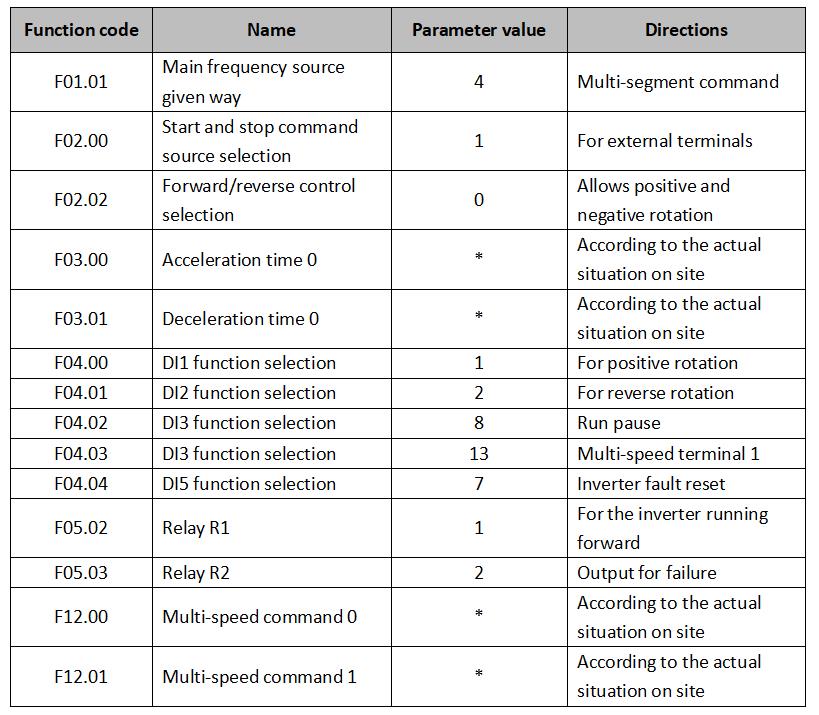

5. Main parameter set

6. Field Application Photos